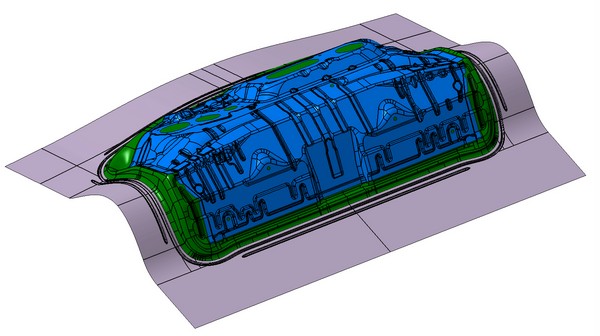

Using customer math data, we design cutter paths for machining kirksite and steel dies in-house. Kirksite is a cost efficient and easily manipulated alloy with approximately half the shrinkage of aluminum. By using kirksite dies, we have more flexibility and are able to better fit your budget and timing requirements. Our recently added CNC machine with a table size of 125” x 97”, along with a new 1,550 ton press will expand our capabilities/capacity to help manage the largest programs as efficiently and cost effectively as possible!

Equipment Lists

Tool Room

- Reid Surface Grinder 6”x 18”

- Harig Surface Grinder 6”x 18”

- (1) Acer, (1) Lebond, (1) Clausing Lathes

- (4) Bridgeport Mills

- (Misc) Part Washers, sandblasters, 5000Lb. Electronic Scale

Sheet Metal

- 150 ton Acco Arbor Press

- 75 Ton Dake Arbor Press

- 80 Ton Kamatsu CNC press Brake

- 80 Ton Chicago Press Brake

- 40 Ton Chicago Press Brake

- 90 Ton Cincinnati Shear 120“

- (3) 55, (1) 40, (1) 50 Ton Iron Workers

- Varity of different saws

- Dallas 18”x 18”air feeder with straightener

- Feed Lease 4000 lb. Cradle with pinch rollers

- Jaybird 6”x 6”Air feed with straightener

- Cicinnati Hydro-Tel Series 60“ travel

- 12“ Disc Sanderer

- Cooper 1200 Lb. X 18“ Cradle

Drill Equipment

- Fosdick 6’ Radial Drill Press

- DoAll 6’ Radial Drill Press

- Cincinnati Bickford Drill Press

- 20” Variable Speed Drill Press

- Procunier Tapping Machine